Ceramill CAD/CAM system (Amann Girrbach)

Right preparation

It is important to choose a suitable preparation technique for ceramics – avoid sharp corners and edges and internal corners, also avoid a cup-shaped preparation. Preparation edge shall be clearly visible and enable thickness of crown material over 0.5 mm.

Registration of face-bow

Traditionally, preparation of dentures starts from taking replica of the situation of the patient. The same visit also includes registration of the face-bow, registrations of movements (condylar inclination, Bennett angle) and registration of central ratio, which will later ensure ideal suitability of work. In our laboratory, it is possible to take a closer look at the Artex system, and we are also pleased to provide assistance in introducing the system.

Preparation of model

Models are prepared with Giroform model system (automatic dosage of gypsum and water, base part of the model is fixed onto a Teflon plate), which prevents excessive expansion of gypsum. Models are articulated according to individual registrations of the patient.

Model digitization

With the help of Ceramill Transferkit, the articulated models are placed into the scanner and scanned exactly in the same position as in the articulator (corresponds precisely to the situation in patient’s mouth) – an anatomically correct transmission of a model into a digital image. The scanner Ceramill map 400 has also been called a “function scanner” due to its great precision.

Computer-aided design (CAD)

Ceramill Mind is an intelligent software developed in cooperation with orthodontic technicians, the characteristic features of which are automatic high precision determination of preparation edge, design of bridges and connectors, and comprehensive tooth database. It enables designing full anatomic restorations simultaneously on upper and lower dental curves. The function of dynamic occlusion minimises the need for grinding of milled crowns.

Virtual occlusion

CeramillArtex is a virtual Artex CR articulator, enabling high-precision design of occlusal surfaces (dynamic occlusal contouring), preserving aesthetic and functional parameters. Virtual articulator calculates automatically the space needed for a cover layer.

Production (CAM)

A 5-axis milling machine is flexible and precise; wet and dry milling takes place in the same machine – milling of different materials (CeramillSintron – millable CoCr, CeramillZolid – monolithic translucent zirconium oxide, Ceramill ZI – zirconium oxide, Vitablocs Mark II / Triluxe forte – pre-tinted contemporary glass ceramics, easy to process and polish).

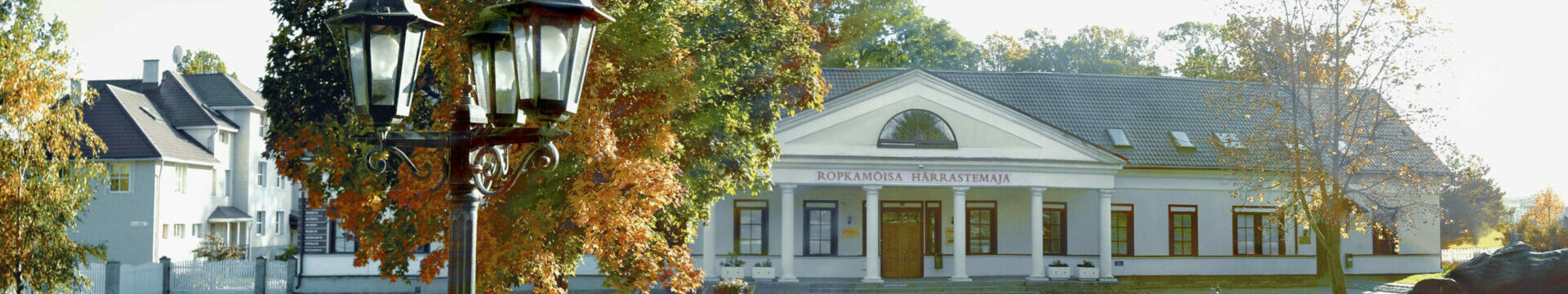

Erakliinik Dentes AS

- Ropka tee 6, Tartu, 50104

- Mo – Fr 8.00 – 19.00

- +372 733 3005

- info@dentes.ee

The surest way is to use Google Maps or Waze on your smartphone.

Responsible employees of the dental lab